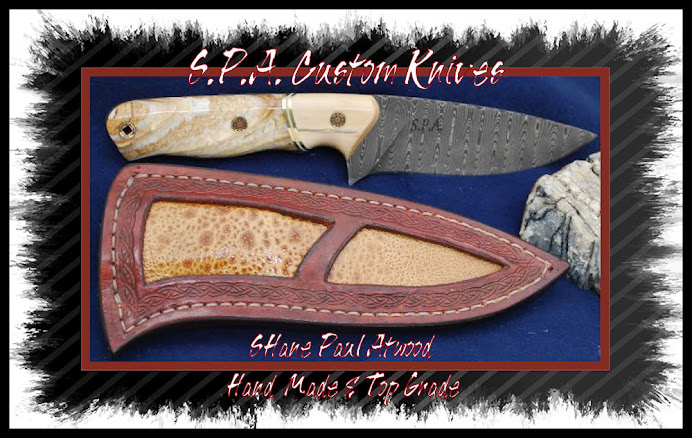

Just see'in if your paying attention Wes!! Wes is one of my buddy's I work with. He is a big time hunter & is lookin for a good knife. We had both been hearing great things about CPM s30v & since I have been trying some new steels lately I thought what the heck, lets give it a whirl. He kinda told me what he was looking look and style wise and just told me to see what I came up with. So here it is if he doesn't like it then tuff! Just kidding! If he doesn't like it then I'm sure I can find someone that will. Heck as good as it cuts maybe I'll keep it! Being this is my 1st time using this type of steel I did a lot of research on the Internet about how to heat treat it the best way. After getting a lot of really different answers I called the stainless steel heat treating expert Paul Bos. He has been doing stainless steels for like 30 years of something and he really knows his stuff. He was kind enough to let me in on his secret recipe for this steel & I believe it worked like a champ. For those of you that don't know I recently went to an awesome knife making seminar at Ed Fowlers place. He taught us that we must test all out knives and know what they can do. I am a firm believer in that concept. I took some of the test I learned while at Ed's and tryed this new born knife out. The first test I tried was the edge flex test. Most makers do this on a soft brass rod. Not Ed Fowler he uses a steel honing rod. So I put a steel rod in my vise & started the edge flex test waiting to hear the edge chip. I was amazed! I flexed the edge with a lot of body weight pressure 8 times and no chips or cracks appeared to the naked eye in the edge. I was very pleased with that so on to the next test. From what I have been told & read you are lucky to get 100cuts on 1/2" sisal or hemp rope on most production knives. Most tests I have seen done only have produced around 60 to 80 cuts. This sweet hunk of steel crunch and sliced it's way through the rope 266 times and was still cutting with the right amount of force, but I was tired. That's A Lot Of Rope To Cut!! I was very pleased with that, so I deemed this knife fit for a handle and to live the rest of it's long life as a respectable knife. I decided to use black linen micarta for a good strong bolster, then a mammoth tooth sigar band, and some very nive Boxelder burl for the main handle. The handle and file work is accented with gray liners and spacers. I was going to post pics of all the rope shavings but I can't seem to find them. So here are some crappy pics of the finished knife. Sorry no sheath as of yet. Thanks for reading and please leave a comment to let me know what ya think. Thanks, Shane